The King Of Chemical Elements - AK Tyagi, Nuberg Engineering Ltd., India, examines the role of sulfur in modern society and its significance for the fertilizer industry.

World Fertilizer, May/June2024

In the realm of chemistry and agriculture, few elements hold as much significance as sulfur. This unassuming yellow element plays a pivotal role in various industries and applications, ranging from fertilizers to chemical production. From its role in sufuric acid production to its significance in various fertilizers, sulfur's versatile applications have garnered the attention of scientists, engineers, and agriculturists. This article delves into the diverse applications and importance of sulfur in modern society

Sulfur and sulfuric acid

One of the most notable applications of sulfur is in the production of sulfuric acid (H2SO4), often dubbed the ‘king of chemicals.’ Sulfuric acid is a fundamental industrial chemical used in the production of a multitude of products, from detergents and paints to batteries and fertilizers. Its widespread use is a testament to the significance of sulfur in driving industrial processes and global economies.The essence of sulfur's influence lies in its dual role as an elemental foundation for industrial progress and an essential nutrient for agricultural growth. In the agricultural sector, sulfur detergents and paints to batteries and fertilizers. Its widespread use is a testament to the significance of sulfur in driving industrial processes and global economies.The essence of sulfur's influence lies in its dual role as an elemental foundation for industrial progress and an essential nutrient for agricultural growth. In the agricultural sector, sulfurfinds its place in various forms to enhance soil fertility and crop yield. Diammonium phosphate, single super phosphate, triple super phosphate, and water-soluble fertilizers all include sulfur as a crucial ingredient. These formulations play a crucial role in providing essential nutrients to plants, aiding in their growth and development.

.png) A sulfur recovery unit (SRU) is a critical component in many industrial processes, particularly in the oil and gas sector. Its primary function is to capture and convert sulfur compounds, which are generated during the processing of sulfur-rich fossil fuels, into elemental sulfur or sulfuric acid. This process (Figure 1) is essential not only to meet environmental regulations but also to recover valuable sulfur resources. The SRU operates through a series of chemical reactions that involve the removal of hydrogen sulfide (H2S) and other sulfur-bearing compounds from various gas streams, such as those from crude oil refining or natural gas processing. These sulfur compounds are converted into more stable forms, contributing to cleaner air and minimising the emission of harmful pollutants. The role of the sulfur recovery unit is crucial in ensuring sustainable and responsible industrial practices while simultaneously addressing environmental concerns.

A sulfur recovery unit (SRU) is a critical component in many industrial processes, particularly in the oil and gas sector. Its primary function is to capture and convert sulfur compounds, which are generated during the processing of sulfur-rich fossil fuels, into elemental sulfur or sulfuric acid. This process (Figure 1) is essential not only to meet environmental regulations but also to recover valuable sulfur resources. The SRU operates through a series of chemical reactions that involve the removal of hydrogen sulfide (H2S) and other sulfur-bearing compounds from various gas streams, such as those from crude oil refining or natural gas processing. These sulfur compounds are converted into more stable forms, contributing to cleaner air and minimising the emission of harmful pollutants. The role of the sulfur recovery unit is crucial in ensuring sustainable and responsible industrial practices while simultaneously addressing environmental concerns.

Nurturing growth

Venturing from factories to farms, sulfur seamlessly transitions from industrial applications to nurturing the Earth. The realm of agriculture witnesses sulfur's contributions in various forms, each catering to the specific needs of crops. As a vital supplier of nutrients to plants, sulfur enriches the rich landscapes of fields and contributes to the intricate balance required for healthy growth

Venturing from factories to farms, sulfur seamlessly transitions from industrial applications to nurturing the Earth. The realm of agriculture witnesses sulfur's contributions in various forms, each catering to the specific needs of crops. As a vital supplier of nutrients to plants, sulfur enriches the rich landscapes of fields and contributes to the intricate balance required for healthy growth

Enriching crop nutrients

Diammonium phosphate (DAP) emerges as a cornerstone in modern agriculture, offering a balanced infusion of essential nutrients to cultivate robust and thriving crops. This fertilizing powerhouse, composed of nitrogen and phosphorus, stands as a testament to scientific innovation meeting agricultural necessity. With its significance spanning from manufacturing to the fields, DAP not only bolsters plant growth but also stimulates root development and flowering, contributing to increased yields and enhanced crop quality. As a versatile nutrient source, DAP ensures that the foundational elements required for healthy plant life are readily available, fostering sustainable agricultural practices and nurturing the promise of abundant harvests.

Gradual release for sustainable agriculture

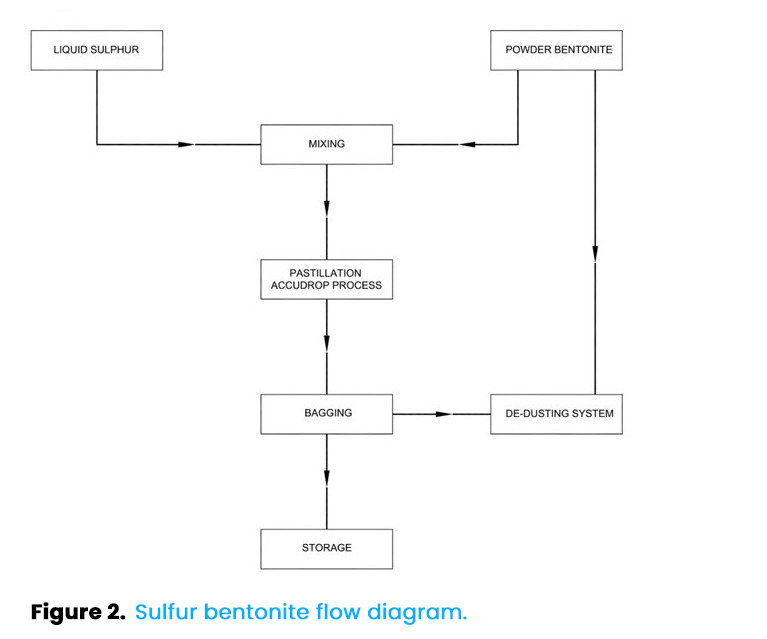

Sulfur bentonite embodies theprinciples of sustainability in farming practices. This fertilizer merges the gradual release of sulfur with the benefits of bentonite clay, offering a dual advantage to both crops and the environment.As the bentonite particles absorb moisture and swell, sulfur molecules are released at a controlled pace, ensuring a steady nutrient supply to plants over time. This measured approach not only minimises the risk of sulfur leaching but also optimises nutrient utilisation by crops. Sulfur bentonite's ability to improve soil structure and enhance water retention further underscores its role in promoting sustainable agriculture. By aligning nutrient release with plant demand, this solution exemplifies a harmonious coexistence between modern farming needs and the preservation of natural resources (Figure 2).

Sulfur bentonite embodies theprinciples of sustainability in farming practices. This fertilizer merges the gradual release of sulfur with the benefits of bentonite clay, offering a dual advantage to both crops and the environment.As the bentonite particles absorb moisture and swell, sulfur molecules are released at a controlled pace, ensuring a steady nutrient supply to plants over time. This measured approach not only minimises the risk of sulfur leaching but also optimises nutrient utilisation by crops. Sulfur bentonite's ability to improve soil structure and enhance water retention further underscores its role in promoting sustainable agriculture. By aligning nutrient release with plant demand, this solution exemplifies a harmonious coexistence between modern farming needs and the preservation of natural resources (Figure 2).

Boosting soil health

Single super phosphate (SSP) and triple super phosphate (TSP) establish their dominance within the sphere of phosphate fertilizers, revitalising soil fertility and fostering robust plant growth.These fertilizers harness the potency of phosphorus to reinforce root systems, amplify flowering, and enhance overall crop vitality.While SSP furnishes an instantaneous surge of phosphorus to plants, enriching their initial growth phases, TSP provides a concentrated source of phosphorus that unlocks sustained nutrient availability. Both fertilizers contribute to the nutritional content of soil, facilitating the enduring well-being of plants and the nurturing of flourishing landscapes. Amidst the embrace of precision and efficiency in modern agriculture, the roles of SSP and TSP remain pivotal, sustaining abundant harvests and resilient ecosystems.

Modern solutions for nutrient delivery

In the evolving landscape of agriculture, water soluble fertilizers emerge as a cutting-edge solution for precise and efficient nutrient delivery. These innovative fertilizers dissolve readily in water, offering a convenient method to administer essential nutrients directly to plants. With their rapid absorption and utilisation by crops, water soluble fertilizers contribute to enhanced growth, increased yields, and improved overall plant health. These fertilizers can be used in different ways to help plants grow better. They can be sprayed on the leaves, used in hydroponic systems, or added to water for drip irrigation. These methods work for different ways of growing crops. By using water to carry the nutrients, these fertilizers make sure that plants get the nutrients they need in a way that is easy and works well. This modern way of using fertilizers helps crops grow better and reduces waste and harm to the environment.

Sulfur's real world impact

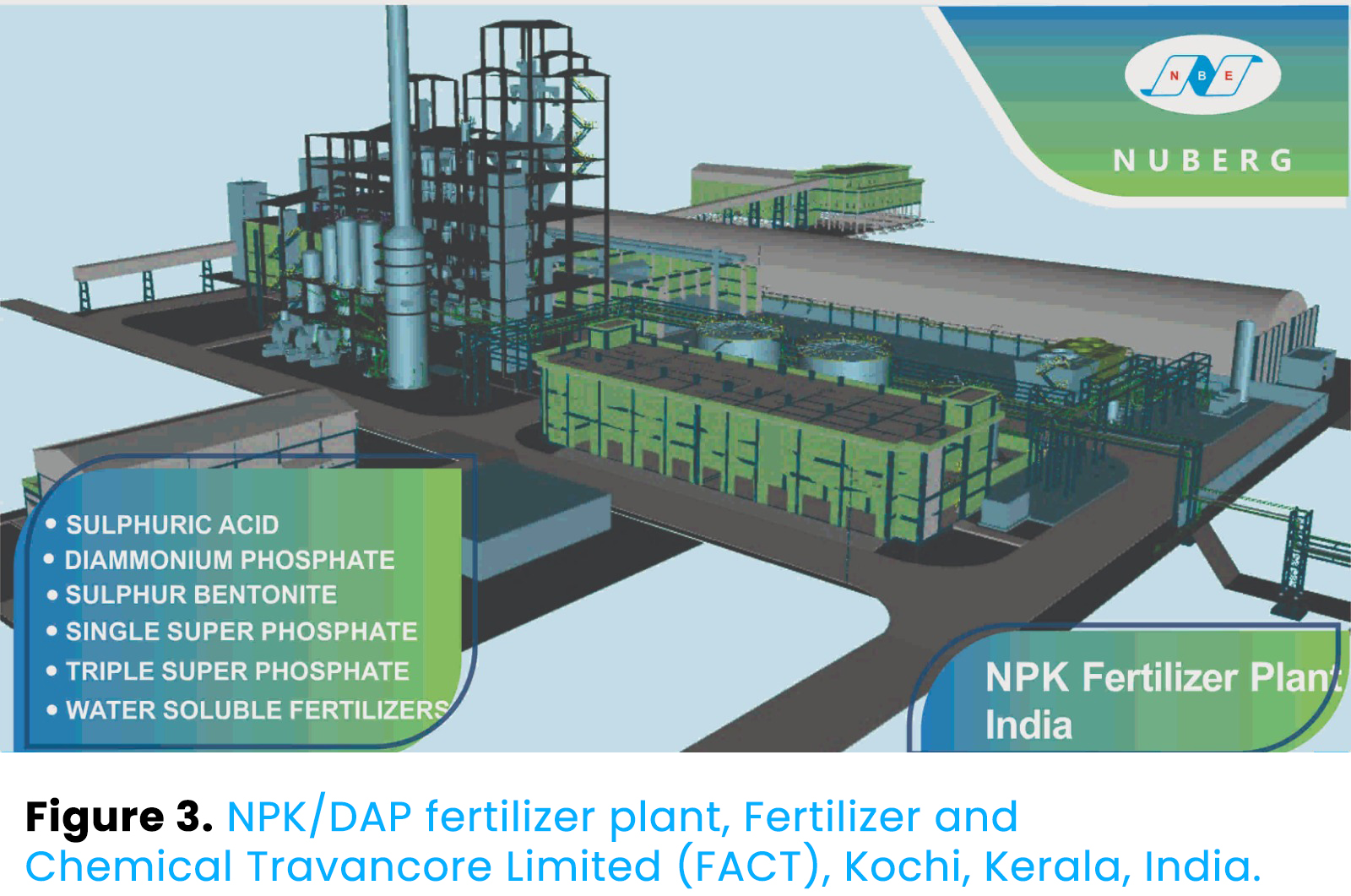

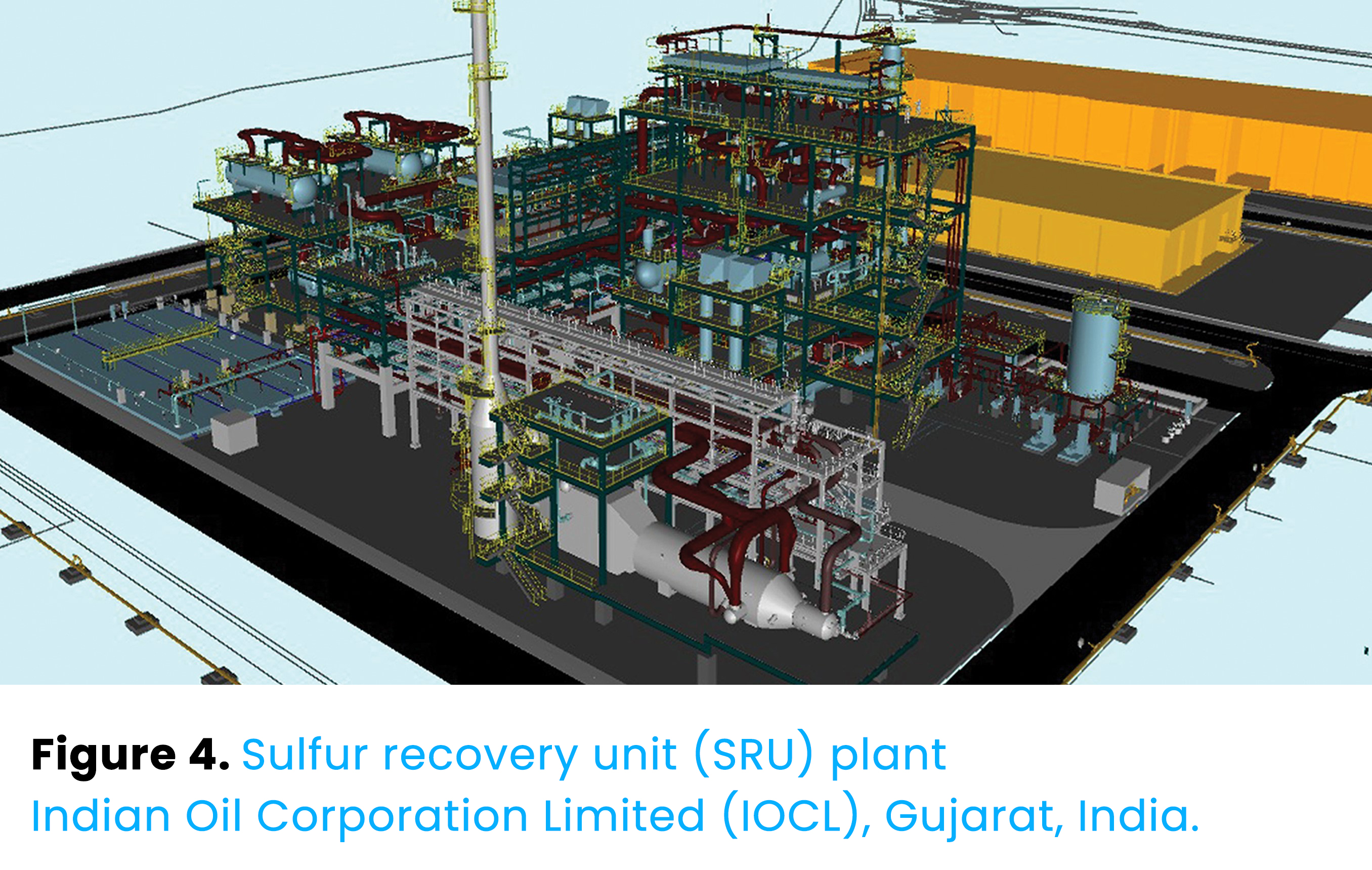

The real-world impact of sulfur manifests through case studies that depict its role in shaping industries and economies.Nuberg EPC and Fertilizer and Chemical Travancore Limited (FACT) partnered to establish the NPK – DAP fertilizer plant in Kochi, Kerala. With a capacity of 1650 tpd, this NPK plant (Figure 3) is an example of a leveraging pipe reactor, pre neutraliser, and mixed process technology.This encompassed the provision of licenses, basic design, detailed engineering procurement, and fabrication, construction, mechanical, electrical, and instrumentation works, all while securing essential statutory approvals. This approach ensured the execution of the project, culminating in the delivery and commissioning of the 1650 tpd NPK plant by June 2024. The products manufactured at this facility will find application in agriculture, contributing to the advancement and sustainability of agricultural practices. This project entails the construction of a sulfur recovery plant, including a sulfur recovery unit (1 x 400 tpd), control room, and substation, as an integral part of the Gujarat refinery's LuPech project. With the sulfur recovery plant (Figure 4) strategically located in Vadodara, Gujarat, within the petrochemical and lube integration project, Nuberg EPC will harness technology to elevate Indian Oil's environmental sustainability and sulfur production capabilities. This plant's adeptness in efficiently recovering sulfur from sour gas, a by-product of the refinery, will significantly contribute to a more eco-friendly and streamlined refining process.

The real-world impact of sulfur manifests through case studies that depict its role in shaping industries and economies.Nuberg EPC and Fertilizer and Chemical Travancore Limited (FACT) partnered to establish the NPK – DAP fertilizer plant in Kochi, Kerala. With a capacity of 1650 tpd, this NPK plant (Figure 3) is an example of a leveraging pipe reactor, pre neutraliser, and mixed process technology.This encompassed the provision of licenses, basic design, detailed engineering procurement, and fabrication, construction, mechanical, electrical, and instrumentation works, all while securing essential statutory approvals. This approach ensured the execution of the project, culminating in the delivery and commissioning of the 1650 tpd NPK plant by June 2024. The products manufactured at this facility will find application in agriculture, contributing to the advancement and sustainability of agricultural practices. This project entails the construction of a sulfur recovery plant, including a sulfur recovery unit (1 x 400 tpd), control room, and substation, as an integral part of the Gujarat refinery's LuPech project. With the sulfur recovery plant (Figure 4) strategically located in Vadodara, Gujarat, within the petrochemical and lube integration project, Nuberg EPC will harness technology to elevate Indian Oil's environmental sustainability and sulfur production capabilities. This plant's adeptness in efficiently recovering sulfur from sour gas, a by-product of the refinery, will significantly contribute to a more eco-friendly and streamlined refining process.

Conclusion

Sulfur's silent but powerful presence in both industry and agriculture underscores its status as an elemental catalyst for progress. From the bustling factories to the fertile fields, sulfur's contributions, facilitated by cutting-edge equipment, shape our world, embodying the synergy of science, nature, and innovation. As we continue to navigate the evolving landscapes of industry and agriculture, sulfur remains an integral component, fostering growth and driving advancement.

© This article was first published in WORLD FERTILIZER | MAY/JUNE 2024

Download PDF