The Big Interview

How is your tie-ups with technology licensors aiding you to overcome challenging EPC projects?

As an EPC company, we partner with various technology licensers as

per our client's needs. They are important to us because their role in

completing an entire turnkey project is really crucial. With an experience

of over 25 years in the industry, we have worked all around the globe

with almost all the technology licensers for products that we operate in.

This makes it easy for us to get technological tie-ups and thus gives us an

additional edge while pitching for a new customer. Association with

various technology partners and licensers have helped Nuberg EPC

hone itself into a globally excelling EPC and LSTK organization in the

market today. We have been able to garner commendable references

from clients that reassure new customers of our capability.

We have been able to position ourselves as the number one player in

the EPC industry for Hydrogen Peroxide and Calcium Chloride. We are

the number two EPC Company for Caustic Soda / Chlor-Alkali plants

globally. We are amongst the world's fastest-growing EPC organizations

with a specialized team of more than 300 engineers providing global

competitiveness.

On the revenue front, for FY 2021-22 which sectors would contribute maximum to the growth of the company?

The year 2020 has been challenging for every industry globally. We were handling various projects that are still incomplete due to pandemic. During the pandemic, we even hired a chartered plane to ferry our engineers to Egypt for timely project completion. The pandemic has forced us to rethink the entire value chain to manage project execution and costs better.

Chemical consumption in developing countries

will expand in traditional businesses while the

western world will look at specialty chemicals to

cater to newer consumer demands. Also, with the

upcoming new realities, we have sharpened our focus

in leveraging digital and automation to add value to

our customers. The enhanced focus on digitization

helps to reduce cost as well.

There is also a strong realization and focus across

the GCC countries to transform their economies

from oil-dependent industries to non-oil dependent

industries. Countries are now building their

capacities instead of importing and diversifying into

various industries including the manufacturing of

specialty chemicals.

Sustained focus in the last 25 years has made Nuberg EPC a number one EPC & LSTK player for Hydrogen Peroxide and Calcium Chloride

Twenty five years of successfully delivering turnkey projects. Can you please share with us a few challenging projects that you commissioned?

Sustained focus in the last 25 years has made

Nuberg EPC a number one EPC & LSTK player for

Hydrogen Peroxide and Calcium Chloride. We are

also identified as the number 2 EPC Company for

Caustic Soda / Chlor-Alkali plants globally. This is

entirely based on the number of successfully delivered

turnkey projects. Our technology know-how and

global experience of operating in more than 32

countries help us deal with laws, statutory

requirements, and societal norms across geographical

diversities. Therefore, we are prepared with all

processes and capabilities to take on these challenges,

and that is a great advantage that we have in terms of

strategy with global size and skills.

We have launched our own R&D facility in

Sweden, EB Nuberg, that intends to contribute with

innovative technology for specialty chemicals. The

country offers the best global talent, and it makes me

proud to share that we have patented technology for

hydrogen peroxide. We are thus amongst the very few

global technological licensers of Hydrogen Peroxide

technology. We are also the global technological

licenser for Sulphuric Acid plants.

We also have our manufacturing division that

produces Pressure Vessels, Reactors, Heat Exchangers,

Columns & Towers, and Tanks. We own a 115,000 sq

m manufacturing plant in Gujarat, which manufactures

large industrial equipment and machinery that caters

to EPC projects as part of Nuberg EPC. We cater to

numerous international as well as large Indian clients

such as big PSUs and private companies.

We hold world-class certifications such as ASME

U2 certification, ISO 9001:2008, ISO 14001:2004,

ISO 18001:2007, and ISO 9001:2015 certification,

and NSIC 9001:2008 certification to ensure quality

processes and International standards.

We have also launched Indian Peroxide Limited

(IPL) that addresses the growing demand for highquality

Hydrogen Peroxide in the Indian market.

Nuberg EPC with these initiatives has not only taken

the Indian EPC industry to a global level but also

raised the bars for them.

With our global outreach, we deliver to multiple

clients in diverse sectors. We have been working with

some of the leading customers which even include Al

Ghaith Industries (Abu Dhabi), Inovyn (Sweden),

FLUODER (Paraguay), ADDAR (Saudi Arabia),

Gulf Chlorine (Qatar), DOSTEL (Turkey), Samuda

Chemical Complex (Bangladesh), AGROCHEM

(Egypt), SARL SASKO (Algeria), AMASSAS Co.

(Ethiopia), Aditya Birla Chemicals (India), Emirates

Chemical Factory (ECF, Abu Dhabi), NCIC (Egypt),

TCI Sanmar (Egypt), Oman Chlorine (Oman).

During the pandemic, we have won 500TPD

Sprea Misr sulphuric acid plant project in

Ramadan, Egypt.

How are you integrating the latest technologies such as IoT, automation for faster completion of projects? Compare to your competitor what is the USP of Nuberg EPC?

I have closely observed the EPC industry and its

developments for more than three decades and have

been a contributor to the capability and business

growth that has taken place in the sector. We hope to

become global leaders in more product areas and

proudly represent Indian excellence.

Under our USP's, we can proudly mention that we

are the single point solution company that has been

working for more than two decades in order to provide

our clients with cost-effective and top-notch quality

plants. We are a team of specialized engineers who have

been dedicated in serving and delivering clients all

across the globe with Engineering, Procurement,

Construction and Commissioning. Such services are

provided for industries like Chemicals and Fertilizers,

Energy & Infrastructure, Steel, Nuclear and Defence.

In addition, with over 60+ greenfield project

executions and zero accident in our history so far, we

hold a global experience to provide safe, reliable and

timely delivery of industrial plants.

Nuberg EPC is fast incorporating the latest in

digital technologies and work processes. This includes

IoT-enabled monitoring and maintenance of projects

and commissioned plants. We are also incorporating

Big Data for smarter design and inspections, AI-driven

intelligent automation, AR and VR for superior safety,

communication, and training, and 3D software for

accuracy in delivery.

Automation in the EPC industry requires unique

skill sets and technical capabilities and that provides a

competitive edge when bidding for projects.

Automation enables the development of the detailed

initial design that is more than 95% fit as the final

design thus enabling real-world estimation of

engineering resources, material, and labour. Such

automation also helps us to focus on construction

execution and related supply chain at an earlier stage

thus compressing timelines and costs.

Nuberg EPC is also moving towards skid-mounted

plants which will drastically compress the time

required to build plants, especially for small size plants.

Nuberg EPC will also be able to provide clients with

significant cost, timeline, and modularity advantages.

With our global outreach, we deliver to multiple clients in diverse sectors

EPC projects have to be delivered on time, else it leads to cost overrun and reputation of EPC players coming under the scanner. During the Pandemic how did you managed to delivered projects on time?

We have noticed some growth in our business still

we have seen the stress that comes with customers

holding the investment decisions. Further, we have

focussed on delivering projects in time despite

lockdown situations. A good example is the Egypt

project where 7-8 months were wasted due to

lockdown and yet we managed to deliver the project

despite extra costs because of our drive and

commitment. Our organization has continued to pay

salaries during that slowdown and even rented

chartered flights for our engineers. The business

decisions have been pushed on backfoot, and the new

customer and prospects are also evaluating the market.

We hope to get some transparency by the next quarter.

Despite the crisis, the majority of our projects are in

full stream execution. Taking learnings of the past

year in the pandemic, we are trying to be more agile

and work digitally. We have also migrated our entire

process to ERP.

For marketing and business development, we utilize

the internet in a big way and generate many leads. With

our global presence, we are available 24*7 to serve our

customers with just a little digital push. Our sales team

is efficient enough to follow-up on the pipeline with

their own IT systems. We have all the necessary stimulation and 3-D software like PDMS and

SOLIDWORKS to facilitate our processes. Customers

can study the plant simulation details that we share

right from small parts to the largest equipment &

machinery. We have different software for each team -

AVEVA E3D for piping, HTRI, PV lite, ISOMAC,

Prosteel, and STAAD.Pro.

We have 2 video-conference rooms, and they are

busy nearly all the time. I have my own videoconferencing

set-up in place, and it has been my

travel replacement from an earlier average of 20 days

in a month. I am even signing deals digitally with

client CEOs, and our documents are as extensive as

200-500 pages.

During the pandemic, we have won 500TPD Sprea Misr sulphuric acid plant project in Ramadan, Egypt

You being a leading global EPC player, what are the challenges you face right from designing to inception to commissioning to final execution of EPC projects?

Acquiring an experienced workforce has been the

greatest challenge we come across. Customizing the

project to local laws and statutory requirements is a

challenge and is a strength. Laws and policies in various

countries keep changing, and we have to and are

expertly able to abide by these changing requirements.

The real challenge is to gain customers' confidence as

global players look for quality. Many global clients prefer

western companies (European and American) in the

belief that the quality may be better. However, Nuberg

EPC as a company is today accepted as a world class EPC

& LSTK organisation - we've established our credentials.

Now what happens is that everywhere we go we

have some references to share with customers on that

market and that gives us an edge. We've done projects

across the world, and we have references to share right

from Europe to central Asia to the Middle East and

everywhere. So, this gives us quite an edge, and yes, of

course, there are countries we are still trying to

penetrate, and there we do get this query.

Our experience concerning payment terms has been

very good with global customers. We've never faced

any challenge over there as long as we meet the delivery

standards - which we are very good at.

Indian embassies from across the world have been

very helpful. We are welcome everywhere we go, and full

support is provided to us. We've had few experiences in

the past where we needed help, and every time we were

supported very well by the local Indian embassy. So,

there is a lot of support from the government otherwise

we won't have been able to flourish the way we are doing.

Can you please take us through few of your outstanding international EPC projects that left a lasting impression on the clients and peers?

Over the years, we have brought ourselves to a level

where we have developed capabilities to deliver

customized projects. Our company can do EPC around

any ideas and products because of our global multi

product capabilities and experiences. For instance, you

are setting up a particular plant that requires a patented

technology (as in how to go from raw materials to the

final product) for the execution process of establishing

a plant. We could make partnerships with global

technology licenses, and our engineering depth and

breadth help us deliver the EPC around it and

commission the plant in a turnkey manner.

For illustration, executing the Sulphur Bentonite

project for National Fertilisers in Panipat was unexplored

territory to us. Consequently, we did the tie-up with

GTC USA for the technology and then leveraged our

strengths to deliver the plant to National Fertilisers.

This is our core strength and competency as an EPC

company to deliver anything, and it is the essence that

also reflects in our brand tagline-Making Ideas Happen.

The global market has faced a major slowdown

amid pandemic both on the demand and supply.

Hence, it is likely to show some growth but still be

slightly depressed. The industry dynamic however is

shifting and has created opportunities for many new

products that we are confident to deliver.

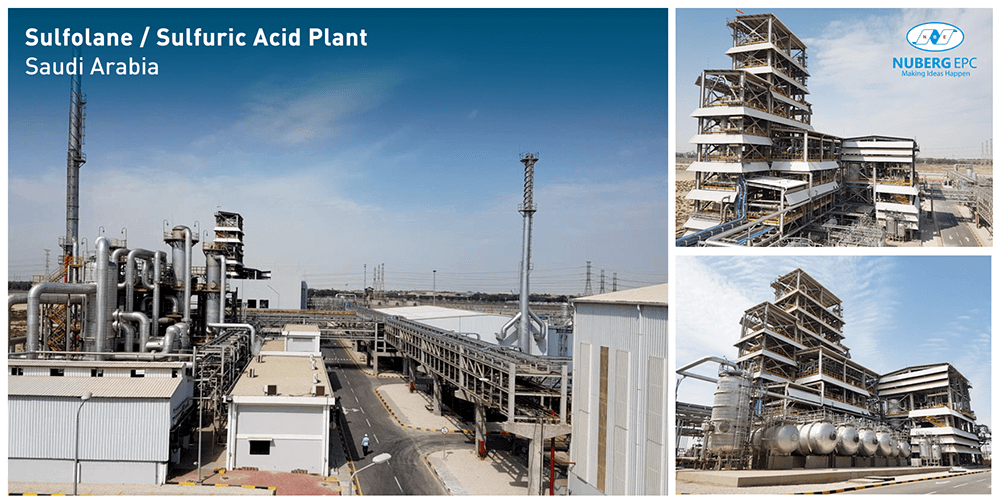

I wish to discuss one such product (Sulfolane),

which we did for a Saudi Arabian client. This product

was again a new specialty chemical that was not

explored by us previously. The next product is Anisole,

and we have seen many such products coming into the

market depending on their domestic dynamics. The

Middle Eastern nations have realized that they can no

longer bank on the oil economy, and they have to

develop non-oil industries. There is a huge demand for

new products, especially Specialty Chemicals, and also

traditional/basic chemical products (Caustic Soda,

Calcium Chloride, Sulfuric Acid, Hydrogen Peroxide,

etc) that were earlier imported. However, now they

desire to build their own capacities.

What is your outlook for the EPC industry for the next four years?

The Covid-19 pandemic negatively affected both the demand and supply side of industrial projects. We believe that the opportunities in the EPC sector are huge and 2021 looks to be the landmark year for the sector. Some key chemicals that will be in demand and need EPC support are Sulphuric Acid market is projected to reach US$ 11.10 billion by 2021. Growing agriculture sector and increasing metal processing activities, along with a rising consciousness about wastewater treatment drive the sulfuric acid market in India; Fertilizer consumption is highest in China and India, followed by the US and with the global population touching 8 billion the caloric requirement is expected to double; Sulfur production is expected to increase by approximately 27% between 2016 – 2021; The global lime market is expected to reach US$50bn by the end of 2026, expanding at a CAGR of 2.5%, according to Persistence market research; Chlor-Alkali market will reach an estimated valuation of USD 55.39 billion by 2027 from USD 49.87 billion in 2019 at a growth rate of 2.9% for the forecast period of 2020 to 2027 according to B-Fortune Business.

Our company can do EPC around any ideas and products because of our global multi product capabilities and experiences

There is also increased focus on exploring usage of

Hydrogen as a clean fuel in existing and new projects,

especially as it is also the feedstock for green chemicals.

For Nuberg EPC, Hydrogen – Green, Grey and

Blue; 2G & 3G Ethanol, Water Electrolysis, Water

Soluble Fertilizers and Next Generation Nutrients are

in focus currently.

Being a responsible corporate citizen, Nuberg EPC

is committed to bring in world class technologies and

processes into India. Similarly, we are already actively

pursuing global opportunities leveraging our Indian

strengths and expanding our global footprints in

upcoming and adjacent sectors.

© This article was first published in EPC World, June 2021.

Media Gallery

EPC World - 25 Years of Turning Ideas into Reality

Siliconindia - Nuberg EPC: Top-Notch industry player in global EPC projects

Industry Outlook - 25 Years of global EPC made From India

Construction And Architecture - Nuberg EPC has developed the habit of setting and improving benchmarks in the industry

Refining & Petrochemicals - Nuberg EPC recognized among the top 30 EPC companies in 2021

Construction Week Online - Nuberg EPC's 25 years of making ideas happen globally and future plans

Construction Week Online - Technology trends that will define the EPC industry of tomorrow

Construction Times - The core engineering talent with the company is our biggest strength

Chemical Engineering World - Healthy pipeline of projects

SiliconIndia - Nuberg EPC: Where Ideas Escalate to Expanses of Engineering Excellence

World Fertilizer - A World of Sulfur

International Cement Review - A new lime plant for Crescent

Process Worldwide - Making Ideas Happen, from Concept to Commissioning

World of Chemicals - EPC demand is rising in all dimensions of chemical industry

Financial Express - Indian firms can be world leaders in EPC

The Sunday Guardian - Engineering companies enthused by Make in India

Download PDF