"The emerging Hydrogen economy is set to create ripple EPC impact, both upstream and downstream, in addition to the huge green electricity requirement. Industries producing currently waste Hydrogen will have a new source of income in addition to carbon credits."

AK Tyagi, CMD, Nuberg Engineering Limited.

EPC&I October 2021

According to The United

Nations Environment Programme

(that sets the global

environmental agenda within

the United Nations system), "in

response to heightening concerns

about the environmental impact of

energy use and worries about the security

of fossil-fuel supplies, Hydrogen,

as an energy carrier, can, in principle,

replace all forms of final energy in use

today and provide energy services to all

sectors of the economy. If hydrogen is

produced without emitting any carbon

dioxide or other climate-destabilising

greenhouse gases, it could form the

basis of a truly sustainable energy system

– the hydrogen economy."

More recently, Union Minister of

State (Independent Charge) Science

and Technology; Minister of State

(Independent Charge) Earth Sciences;

MoS PMO, Personnel, Public Grievances,

Pensions, Atomic Energy and

Space, Dr Jitendra Singh said that

India has the potential to become

Global Hub of Green Hydrogen by

2030 with global annual export potential

expected to be 10.4 million tonnes

to East Asia and EU, amounting to

nearly US$20-billion market. Aspirational

goal for India is 'Hydrogen 212'

– Green hydrogen generation cost of

less than $2.00/kg, Green hydrogen

storage + distribution + refuelling cost

of less than $1.00/kg and replacement

of incumbent end-use technology with

green hydrogen technology with ROI

of less than two years.

The minister informed that the

Government is already encouraging

adaptation of Hydrogen fuels and

technology for the mobility sector and

many industries like Steel, Cement,

and Glass Manufacturing Industries

have already started using Hydrogen

for heating requirements. Significantly,

in March 2021, Nuberg EPC was

commissioned to build India's first

commercial scale Hydrogen Purification

(fuel cell grade), Compression,

Storage and Dispensing Facility. The

1.5 TPD project is to be completed in

just 36 weeks from FOA, and involves

generation of ultra-pure hydrogen and

its storage at extremely high pressure.

Based on Absorption technology,

the plant will produce 99.997 per cent

pure Hydrogen. The storage facility

will contain record high pressure and

will be built using state-of-the-art

compression and storage system with automatic priority in dispensing the

gas. Hydrogen produced at the plant

will be used as a fuel for vehicles.

The success of the plant will enable

a revolution in India. Fuel cell vehicles

carry a hydrogen tank and produce

their own electricity, unlike other electric

vehicles, and, thus, cause zero pollution.

Countries like Norway, US,

Germany, Japan, South Korea, and

China are already running hydrogenfuelled

cars and buses. Already, there

are several hydrogen projects tendered

in India and many more are in the

pipeline.

Hydrogen is also being actively

evaluated and preferred as the fuel to

cater to India's enormous demand for

EPC in the next few years. Investment

of `8.00-lakh-crore is anticipated in

the Indian chemicals and petrochemicals

industry by 2025. 'Make in India'

across sectors, and India's increased

defence self-sufficiency needs, will also

create urgency for corresponding EPC.

CRISIL has already projected higher

growth of 15 per cent for mid-sized

EPC players this fiscal.

Globally, decarbonising energy and

other industries using hydrogen will

require investment of almost $15-trillion

between 2021 and 2050, according

to the Energy Transitions Commission

(ETC). Hydrogen use is forecast

to grow to 500-800 million tonnes a

year by mid-century, accounting for

15-20 per cent of total final energy

demand, from 115 million tonnes currently.

Producing this green hydrogen will

need zero-carbon electricity supply to

increase by 30,000 terawatt hours

(TWh) by 2050, on top of 90,000

TWh needed for decarbonisation generally.

This will require investment of

around $15-trillion, peaking in the late

2030s at around $800-billion per

annum, not just for hydrogen production

but for the electricity system to

support the massive increase in hydrogen

use, says ETC.

The emerging Hydrogen economy

is set to create ripple EPC impact,

both upstream and downstream, in

addition to the huge green electricity

requirement. Industries producing

currently waste Hydrogen will have a

new source of income in addition to

carbon credits.

Hydrogen production in symbiosis

with increasing number of renewable

power sources whose power capacity

is dependent of nature's unpredictability

promise a stabilised electric

power environment and will help

nations further fast-track renewable

power projects.

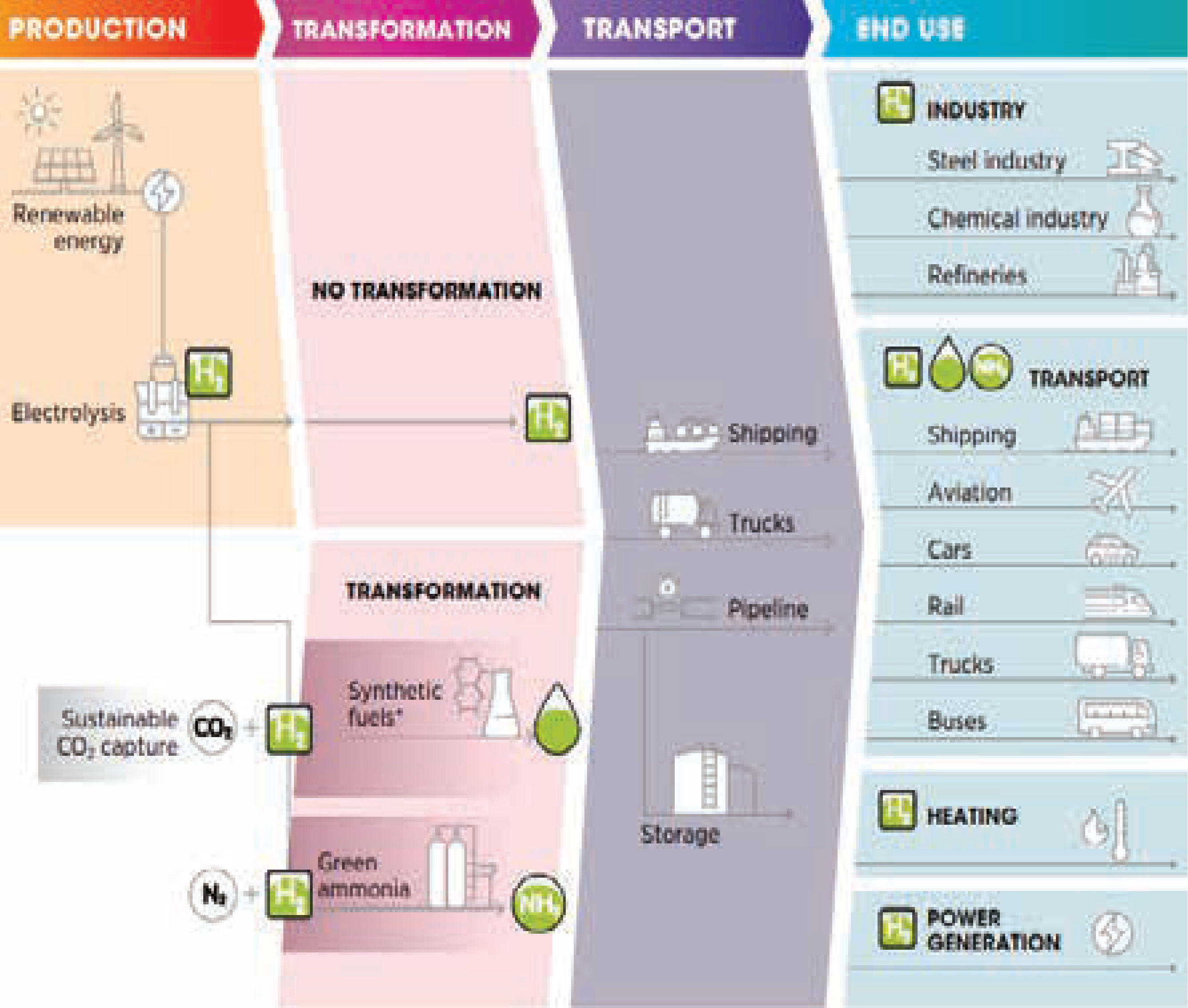

The consumer sectors of Hydrogen

economy will force a re-imagining of

some key products starting with automobiles

where heavy commercial vehicles

will have a viable zero emission

fuel (as electric HCV are seemingly not

viable in terms of cost and performance).

This will lead to fast tracking

of hydrogen distribution infrastructure

that will need to be created with all its

storage, pipeline, and pump components.

The availability of this hydrogen

refuelling infrastructure will bring

about a rethink in the electric vs

hydrogen cars equation resulting in

redesign for the new fuel source.

According to The International

Renewable Energy Agency (IRENA),

"many other uses of green hydrogen

include the additional conversion of

hydrogen to other energy carriers and

products, such as ammonia, methanol

and synthetic liquids. These uses can

increase the future demand for hydrogen

and can take advantage of possible

synergies to decrease costs in the green

hydrogen value chain. Green hydrogen

can, in fact, improve industrial competitiveness,

not only for the countries

that establish technology leadership in

its deployment but also by providing

an opportunity for existing industries

to have a role in a low-carbon future.

Countries with large renewable

resources could derive major economic

benefits by becoming net exporters of

green hydrogen in a global green

hydrogen economy."

Countries across the globe are

increasing their policy support for

the Hydrogen Economy. These

enabling policies cover several

aspects of the hydrogen economy –

from electricity generation for electrolysis

to infrastructure enablement,

financial models, and consuming

industry motivation.

The world is, thus, set to enter a

cleaner and less polluted era, and

this will create a massive ask of the

global EPC industry. At Nuberg EPC,

we are committed to providing world

class technologies and processes to

Indian and global industries in this

endeavour.

© This article was first published in EPC&I, October 2021.

Media Gallery

EPC&I - HYDROGEN ECONOMY – THE NEXT BIG WAVE?

Infrastructure Today - EPC Industry is Calibrating to a New Normal

Construction World - AK Tyagi, CMD, Nuberg Engg: EPC industry is calibrating to new normal

Construction Times - The core engineering talent with the company is our biggest strength

Chemical Engineering World - Healthy pipeline of projects

SiliconIndia - Nuberg EPC: Where Ideas Escalate to Expanses of Engineering Excellence

World Fertilizer - A World of Sulfur

International Cement Review - A new lime plant for Crescent

Process Worldwide - Making Ideas Happen, from Concept to Commissioning

World of Chemicals - EPC demand is rising in all dimensions of chemical industry

Financial Express - Indian firms can be world leaders in EPC

The Sunday Guardian - Engineering companies enthused by Make in India

Download PDF